It enables a company to make informed decisions, stay competitive, and increase profitability. On the other hand, if production costs decrease, they can look at ways to reduce production costs without https://www.instagram.com/bookstime_inc compromising quality or profitability. By understanding how product and production costs are related, businesses can more effectively manage their operations and ensure success. You can accurately determine your product’s cost by considering all three components. Knowing this information is essential for setting competitive prices and maximizing profits.

Accounting Guide

In the long term, a business that consistently under product costs consist of costs its products or services will likely become unprofitable and may have to close down. If businesses are overcosting their products or services, they may miss out on sales to price-sensitive customers. This can harm the business in the short-term as they will make less revenue than they could have if they had priced their products or services more competitively. Also, they might not have a clear idea of how much their products or services cost so they might price them too low. Whatever the reason, undercosting can be a risky pricing strategy that can lead to financial problems for businesses.

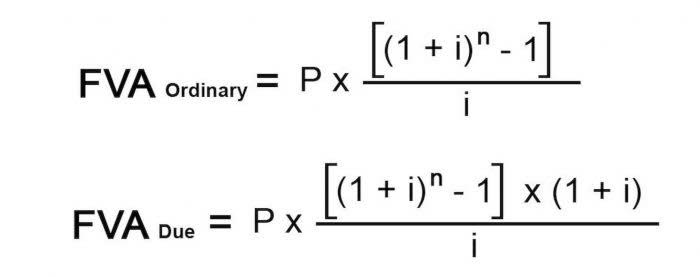

Formula

- This method is typically used in manufacturing environments where products are made in large batches.

- Breaking down your costs into materials, labor, overhead, and other expenses reveals insights into where your money is going.

- To keep things simple, production costs are expenses incurred when producing your product or service.

- If the employee’s work can be directly tied to the product, it is direct labor.

- Indirect labor consists of the cost of labor that cannot, or will not for practical reasons, be traced to the products being manufactured.

- Before you even begin developing a product, you need a clear plan for what you’re building.

By understanding their cost structure, businesses can better identify opportunities for improvement and make informed decisions about how to price products in the marketplace. The term “product cost” refers to the expenses incurred during a product’s manufacturing process. As you have arrived at the cost per unit of your products, you can use these numbers as a jumping-off point for determining their optimal selling prices.

Why Should Manufacturing Managers Worry About Product Overcosting Or Undercosting?

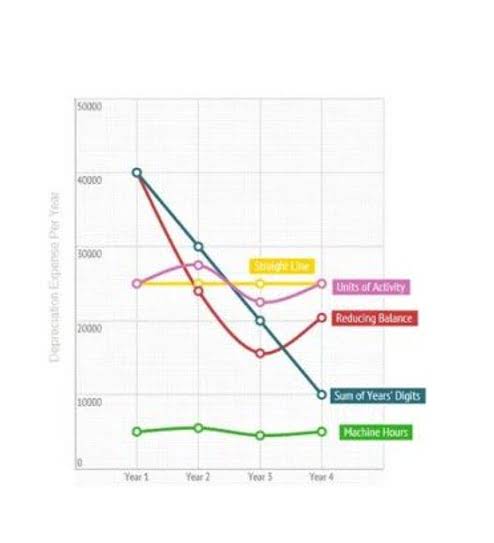

This formula incorporates all the components of product costs and adds them together. If one of those components is absent, companies can ignore them in the calculation. Cost accounting also involves analyzing various costs and reporting them using several formats. These formats, also known as costing techniques, allow companies to derive their product costs.

For companies providing services, these consist of costs incurred on rendering services. Cost of production is the expenses you incur while producing your product or service. Price relates to how much your customers are going to pay for your finished product or service. Creating a budget for factory overhead https://www.bookstime.com/bookkeeping-services/chicago costs aids in estimating variable and fixed overheads, providing insights into cash disbursement needs. Nevertheless, every company should at least know their product cost as a bare minimum, as this knowledge alone can be used to make effective pricing decisions. When combined with activity-based costing, product costing can be a powerful tool for running an even more efficient business.